2026 Best Grinding Disc Options for Every Application and Need?

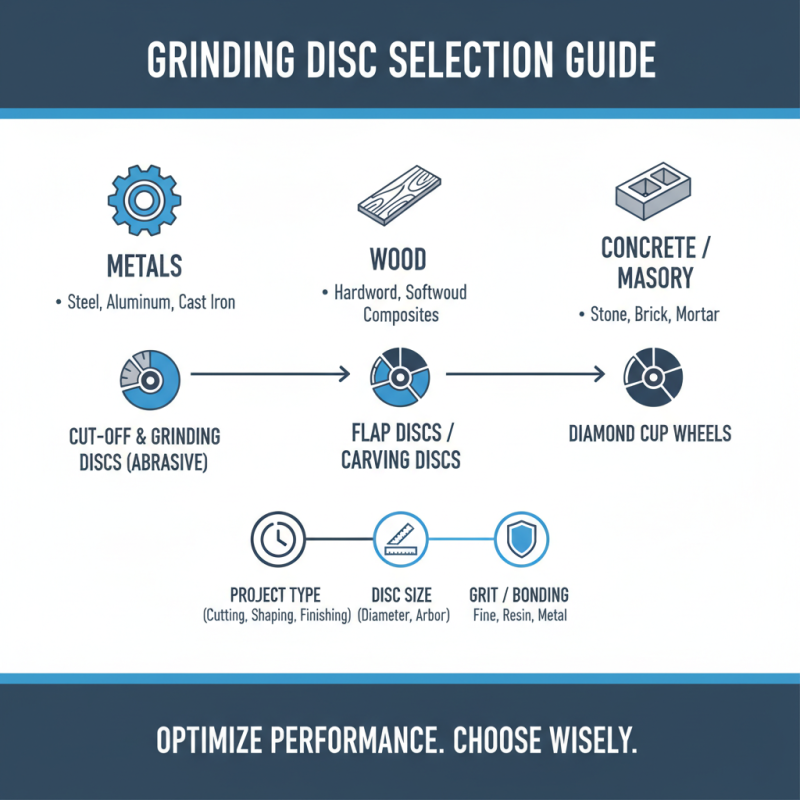

Choosing the right grinding disc can be a complex task. There are various types and applications to consider. Whether you need to grind metal, stone, or other materials, the right disc makes all the difference.

In 2026, many options are available. Each grinding disc has unique features that cater to specific needs. Some are designed for smooth finishes, while others are meant for heavy material removal. Knowing the characteristics of each type can save time and frustration. It can also enhance the quality of your work.

Selecting the ideal grinding disc requires careful thought. Often, users overlook specific details that affect performance. The wrong choice can lead to inefficiency and poor results. Consider the project at hand. Reflect on what tools will truly serve your purposes best. This guide aims to simplify the selection process and help you choose with confidence.

Types of Grinding Discs for Different Materials and Applications

Grinding discs are essential tools in various applications. Choosing the right type can greatly affect performance. Different materials require specific discs, tailored to their unique properties. For instance, metal grinding discs are designed to withstand high temperatures and provide a smooth finish. These discs excel in metal fabrication and repair work.

Ceramic discs, on the other hand, are excellent for porous materials like concrete. They offer durability and longer life, but they can't be used for softer surfaces. This mismatch can lead to poor results. Additionally, some users may forget that diamond grinding discs are ideal for hard materials such as granite and marble, providing precision cuts.

It's important to consider the thickness and grit of the disc as well. Thicker discs tend to last longer but may limit maneuverability. Less experienced users sometimes neglect the need for a proper angle while grinding. This oversight can cause uneven wear on the disc and affect the quality of work. Reflecting on these choices can lead to better outcomes in the long run.

Key Factors to Consider When Choosing a Grinding Disc

Choosing the right grinding disc is crucial for successful projects. There are several factors to consider. First, understand the material you'll be working with. Metals, wood, or concrete require different types of grinding discs. Each material has its own unique characteristics that affect performance.

Next, think about the disc's grit size. A finer grit offers a smoother finish, while a coarser grit removes more material quickly. It's essential to match the grit to the job. If you use the wrong grit, your results might disappoint. For example, a heavy material removal may turn into an uneven surface with a fine grit.

Also, consider the disc's thickness. Thinner discs are great for precise cuts, but they can wear out faster. A thicker disc might last longer but could compromise cutting speed. Reflect on your needs and how often you'll use the disc. The perfect choice often depends on the project. Balancing these factors can be challenging. But finding the right disc can lead to better results. Take your time to evaluate your options carefully.

Top Brands and Their Best-Selling Grinding Disc Models

When looking for the best grinding discs, several top brands dominate the market. These brands offer models tailored to specific applications, ensuring users can find the right fit for their needs. According to industry reports, the global grinding disc market was valued at approximately $2 billion in 2022, reflecting a steady growth trajectory. This growth underscores the importance of having reliable products.

A popular choice for metalworking is the abrasive grinding disc, known for its durability and efficiency. Experts highlight that these discs can cut down processing time by up to 30%. However, there’s a catch; not all discs perform equally across materials. Users often face challenges, especially when selecting a disc for concrete versus stainless steel. Misalignment can cost both time and money, signaling the need for careful consideration.

Another avenue worth exploring is the resin-bonded grinding discs. They excel in achieving smooth finishes but might wear out quicker than other types. This trade-off raises questions about longevity versus finish quality. While many users prioritize the finish, it’s crucial to evaluate the cost-effectiveness of each option. Not every top model will meet every professional requirement. Understanding specific needs is vital for making educated choices in this diverse market.

2026 Best Grinding Disc Options for Every Application and Need

Safety Tips and Best Practices for Using Grinding Discs

Using grinding discs can be straightforward. However, safety is crucial. Industry data shows that improper use can lead to accidents. According to a report by the International Safety Association, nearly 30% of grinding injuries stem from user error. Proper training and awareness of best practices can reduce this risk significantly.

When using grinding discs, always wear appropriate personal protective equipment (PPE). A good rule is to have safety goggles, gloves, and a face shield. Distractions can lead to mistakes. Focus on the task at hand. Moreover, inspect the disc before use. Check for cracks or chips. A damaged disc can break under pressure. This is a common pitfall that many users overlook.

Tip: Always secure your workpiece. This minimizes movement while grinding. It can help you maintain better control. Proper positioning of both yourself and the tool makes a difference. Incorrect stance can lead to mishaps. Being mindful of your surroundings is also vital. Look for hazards in your workspace before starting. Safety should never be an afterthought.

Maintenance and Care for Longevity of Grinding Discs

Maintaining grinding discs is essential for optimal performance. Proper care can extend their lifespan significantly. According to a market report by Research and Markets, effective maintenance can improve grinding efficiency by up to 35%. This statistic highlights the importance of regular checks and care routines.

Cleaning and inspecting grinding discs should be routine. Accumulated debris can hinder performance and shorten lifespan. Regularly removing residues can prevent overheating. Overheating is one of the major causes of disc failure. Using a soft brush or compressed air can be helpful in this regard. Inadequate cleaning is a common mistake.

Storage conditions are equally important. Discs should be stored in a cool, dry place. Excess moisture can lead to rust, which compromises integrity. A study by the American National Standards Institute suggests that about 20% of disc failures are due to poor storage. Taking care to store discs correctly is often overlooked.