Top 10 Floor Polishing Pads for a Shiny Smooth Finish?

In the world of maintaining pristine floors, the right tools make all the difference. John McArthur, a renowned expert in floor care, emphasizes that “a quality Floor Polishing Pad can transform tired surfaces into stunning reflections.” Selecting the best pads is essential for achieving that desired shiny, smooth finish.

There are many options available in the market. Understanding which Floor Polishing Pad works best for your specific floor type is crucial. For instance, soft pads are ideal for delicate finishes, while harsher pads are suited for tougher surfaces. It's important to balance effectiveness with the potential for wear on your floors.

Not all pads deliver the same results. Some may leave scratches or dull spots. Testing is necessary to ensure you choose the right product. Always remember, a shining floor not only enhances your space but also reflects how much you care for your home. Making a thoughtful choice in Floor Polishing Pads will yield long-lasting benefits.

Overview of Floor Polishing Pads: What You Need to Know

Floor polishing pads are essential for achieving a shiny, smooth finish on various floor types. These pads come in different materials, grits, and colors. Knowing the right type can significantly impact the final look of your floors. For instance, softer pads are perfect for glossy finishes, while harder pads work well for removing deep scratches.

Understanding your floor surface is crucial. Different materials require different pads. Marble may need finer pads, whereas concrete often benefits from coarser grits. Using the incorrect pad can lead to damage or less than desirable results. It's important to experiment and adjust your approach based on initial outcomes. Sometimes, a pad that works for one area may not suit another. Test patches can guide your choice.

Polishing requires patience and attention to detail. Rushing can lead to uneven finishes. Watch for dull spots as you work. If something doesn’t seem right, take a step back. Adjust your technique if necessary. The quest for that perfect shine involves trial and error. The right pad can make all the difference, but learning through your mistakes is just as valuable.

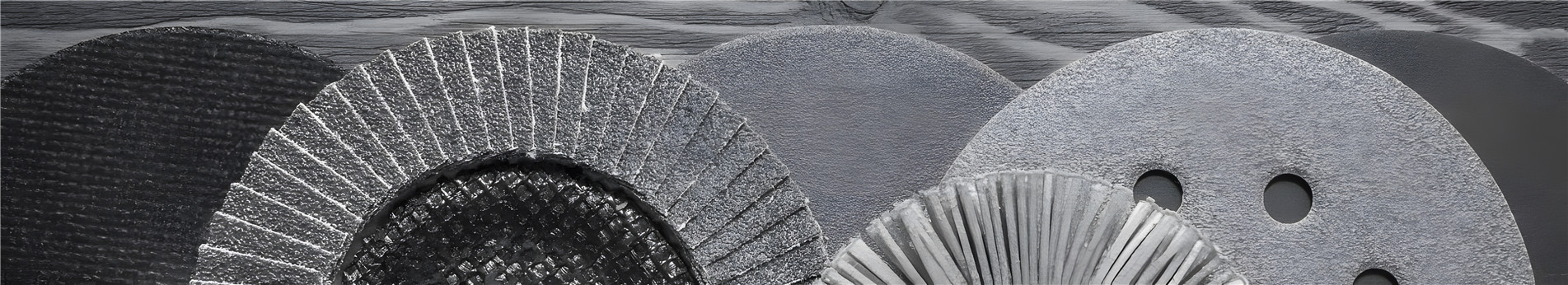

Types of Floor Polishing Pads: Materials and Uses

When considering floor polishing pads, understanding the types available is crucial. Floor polishing pads are primarily made from different materials, each designed for specific tasks. The most common materials include fiber, foam, and diamond. Fiber pads are excellent for everyday cleaning, providing a decent shine. Foam pads, on the other hand, are more versatile, suitable for light polishing and scrubbing. Diamond pads are often used for heavy-duty polishing, offering a high-gloss finish on hard surfaces.

In a recent industry report, 75% of professionals noted that using the right pad significantly impacts floor appearance. Different pads can achieve various textures and levels of shine. For high-traffic areas, consider using pads with more durability. They may cost more, but their longevity often justifies the investment. Additionally, choosing the correct grit level is essential. A lower grit (rougher) pad is best for aggressive stripping, while higher grit pads smooth surfaces for a shinier finish.

Tip: Always test a small area before full application. This helps avoid using the wrong pad, which could damage your flooring. Furthermore, remember to clean your pads regularly. Dirty pads can leave scratches and dull areas on the floor, undermining your polishing efforts. Keeping materials clean can enhance performance and prolong the life of the pads.

Top 10 Floor Polishing Pads for Various Surfaces and Finishes

When it comes to floor polishing pads, choosing the right type is crucial for achieving a glossy finish on different surfaces. The market is filled with options, yet not all pads work equally well on various materials. For example, concrete floors require a different pad than hardwood or tile. Industry data suggests that nearly 67% of floor maintenance professionals experience challenges in selecting appropriate pads for specific surfaces. Understanding these differences can lead to more efficient maintenance routines.

The compatibility of polishing pads with surface types directly impacts their performance. According to a recent report by the Floor Maintenance Association, improper pad selection can lead to a 40% increase in labor costs. For harder surfaces like marble, a finer grit is recommended, while medium grits work best for softer woods. However, many users overlook this detail, risking unsatisfactory results.

Moreover, the lifespan of polishing pads varies significantly based on usage and surface material. Research shows that pads used on high-traffic areas wear out 50% faster compared to those in low-traffic regions. This inconsistency can pose concerns for maintenance budgets. Users should frequently assess their pad condition. It's vital to remember that not all pads will deliver the same results. A little attention to detail can go a long way in maintaining stunning floor finishes.

Top 10 Floor Polishing Pads for a Shiny Smooth Finish

How to Choose the Right Floor Polishing Pad for Your Needs

Choosing the right floor polishing pad can feel overwhelming. Consider the type of flooring you have. Different materials require different pads. For instance, hardwood, tile, and concrete each have distinct needs. A pad made for one surface may damage another. Research is crucial.

Next, think about the level of shine you desire. Some pads are designed for a high gloss finish, while others provide a more subtle sheen. The grit of the pad impacts the finish. Finer grits create a smooth surface but may take more time. Sometimes, a coarser pad might seem better, but it can leave scratches.

Don't forget to match the pad to your machine. Not all pads fit all machines. Compatibility is key; being mindful of this can save you time and hassle. Try to test a few options. You might find that the first choice isn't the best one for your floor. There is no perfect solution. Each floor is unique and requires thoughtful consideration.

Top 10 Floor Polishing Pads for a Shiny Smooth Finish

| Pad Type | Grit Level | Ideal Use | Material | Durability |

|---|---|---|---|---|

| Diamond Polishing Pads | 50 - 3000 Grit | Concrete, Marble | Diamond Resin | High |

| Synthetic Pads | Medium | Vinyl, Linoleum | Polyester | Medium |

| Natural Fiber Pads | Coarse | Wood, Bamboo | Cotton, Jute | Low |

| Heavy Duty Floor Pads | Medium | Commercial Floors | Nylon, Polyester | High |

| Polishing Floor Pads | 1000 - 3000 Grit | Marble, Concrete | Resin | Medium |

| Scrubbing Floor Pads | Coarse | Tile, Stone | Synthetic | Medium |

| Burnishing Pads | Fine | Glossy Finish | Polyester | High |

| Dry Floor Pads | N/A | Wood, Laminates | Synthetic | Medium |

| Eco-Friendly Pads | Medium | Various Floors | Natural Fibers | Medium |

| Velcro Backed Pads | Fine | Various Floors | Felt/Polyester | High |

Maintenance Tips for Floor Polishing Pads to Ensure Longevity

Proper maintenance of floor polishing pads is crucial for achieving a shiny, smooth finish. Industry studies show that well-maintained pads can last up to 50% longer than neglected ones. Regular cleaning is essential. After each use, pads should be rinsed with water to remove the buildup of dirt and residue. This simple step can prevent the pads from becoming less effective over time.

Storage also matters. Pads should be stored in a cool, dry place. Avoid stacking them directly on top of each other. This practice can lead to deformation and reduced effectiveness. Periodic inspections should be made. Look for signs of wear and damage, which can compromise their ability to polish floors effectively. Keeping a maintenance schedule can help in identifying when pads need replacement.

Training staff on the right techniques is vital. Incorrect use of pads can lead to premature wear. The cost implications of replacing worn-out pads are significant. Research indicates that maintaining pads properly saves businesses around 30% in replacement costs annually. With proper care and attention, floor polishing pads can provide excellent results and longevity.